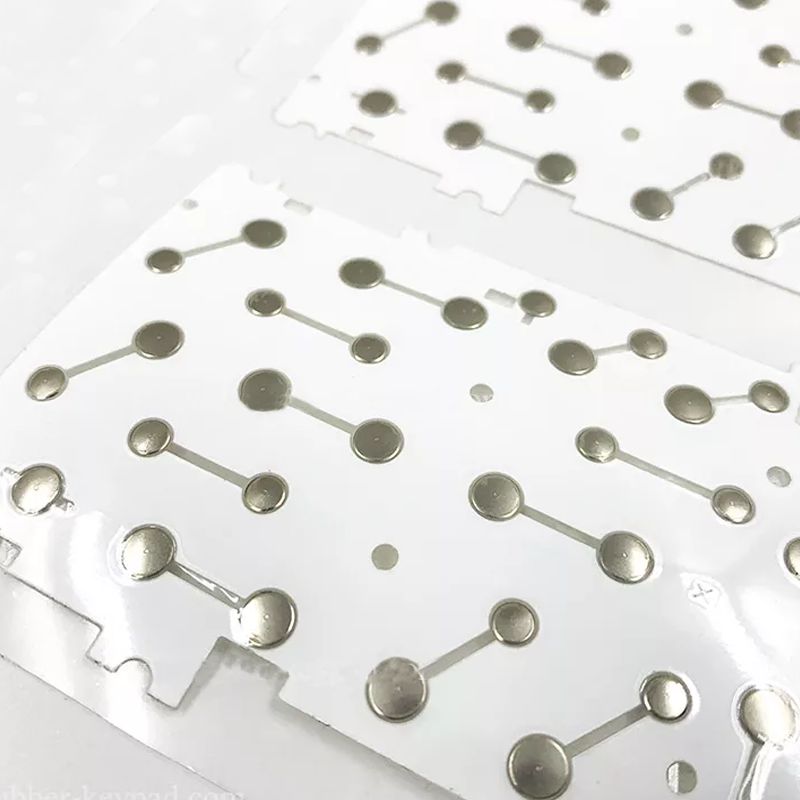

Eco-Friendly Metal Dome Silicone Keypads from China Factory

Overview:

Enhance your device’s performance with our Metal Dome Enhanced Silicone Keypads. Designed for comfort, precision, and responsive feedback, each key press delivers exceptional satisfaction. Utilizing advanced metal dome technology, these keypads offer superior durability, longevity, and moisture resistance, thanks to a waterproof membrane on the back. Our eco-friendly keypads are ISO9001:2015 certified, guaranteeing consistent reliability. Innovative printing techniques ensure both functionality and visual appeal, seamlessly integrating into various electronic devices. Featuring a non-stick surface to prevent debris accumulation, maintenance is effortless. Manufactured using compression molding, our versatile and adaptable Premium Metal Dome Silicone Keypads epitomize the perfect blend of form and function, catering to a wide range of applications across diverse industries.

Specifications:

| Attribute | Details |

| Detection Method | Correlation Type |

| Certification | SGS, ROHS, CE |

| Materials | Silicone Rubber |

| Environmental Friendly | Yes |

| Actuation Force | 50-300g |

| Surface Coating | PU Coating, Matt Smooth Coating, Epoxy Coating |

| Origin | Xiamen, China |

| Brand | OEM/ODM |

| Color | Custom |

| Work Temperature | -40°C to 230°C |

| Contact Resistance | 10-200 ohm |

| Legend | Silkscreen, Laser Etching |

| Conductive Way | Conductive Printing, Carbon Pills, Metal Dome |

| Transport Package | Poly Bag, Carton Boxes |

| Production Capacity | 50,000 pcs/week |

Key Advantages of Our Silicone Keypads:

– Superior Touch Sensation and Anti-Dust Properties

– Designed to provide an excellent tactile experience while resisting dust accumulation, ensuring a clean and responsive interface.

– Cost-Effective for Bulk Orders

– Ideal for large-scale production, offering significant cost savings without compromising on quality.

– Durable and Long-Lasting

– Engineered for longevity, these keypads maintain their performance over extended periods, making them a reliable choice for various applications.

Comprehensive One-Stop Service for Silicone Keypads:

– Complete Project Management: Overseeing every phase of silicone keypad production, from initial design and prototyping to full-scale manufacturing and final delivery.

– Integrated Supply Chain Solutions: Collaborating with suppliers and partners to optimize procurement processes and ensure cost-effective solutions.

– Custom Packaging and Logistics: Providing tailored packaging options and efficient logistics management to accommodate global distribution needs.

– Exceptional After-Sales Support: Offering continuous customer support, including technical assistance, warranty services, and product maintenance.

Production Process of Conductive Keypads:

- Design Phase: Develop a comprehensive design focusing on form, key layout, and overall structure.

- Material Preparation: Source and prepare conductive materials, including silicone rubber, carbon powder, metals, and backing material.

- Conductive Layer Creation: Formulate the conductive layer by blending silicone rubber with carbon powder or incorporating a metal mesh.

- Precision Printing: Employ advanced printing techniques to accurately apply key patterns and symbols onto the conductive layer.

- Assembly: Combine the conductive layer with the backing material, ensuring precise alignment for optimal performance.

- Curing Process: Apply controlled curing to strengthen adhesion and enhance durability.

- Quality Assurance: Conduct rigorous testing to evaluate sensitivity, electrical conductivity, and visual appeal.

- Packaging: Securely package the keypads to prevent damage during transportation and ensure safe delivery.

![]()