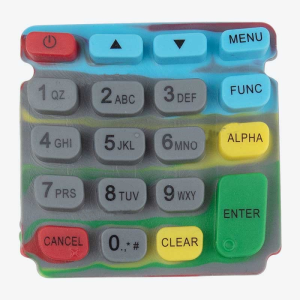

Bulk Order High Standard Dual Color Silicone Rubber Keypad

Overview:

Our dual-color silicone keypads offer a visually appealing design enhancement, combining functionality with aesthetic appeal. The production process involves compression molding, which allows us to create keypads with a hard durometer silicone rubber top layer. This top layer provides a tactile feel similar to plastic while avoiding the costs associated with plastic molding. Although the dual-color option may require additional production time and an extra mold tool, it results in a distinctive and attractive keypad. This approach blends durability with a sleek appearance, meeting the needs of customers who value both functionality and visual appeal.

Surface Treatment Options for Dual-Color Silicone Keypads:

- Laser Etching:

– Employ advanced laser technology to precisely etch text or symbols onto the keypad surface, ensuring clarity and long-lasting visibility.

- Silkscreen Printing:

– Use a fine mesh screen to apply ink onto the keypad, achieving sharp and detailed legends or symbols with high accuracy.

- Spray Coating:

– Apply a uniform protective spray coating to the keypad, enhancing its durability and resistance to everyday wear and tear.

- UV Coating:

– Apply a UV-curable coating to the keypad and cure it under ultraviolet light, resulting in a resilient and scratch-resistant surface.

Manufacturing Process for Dual-Color Silicone Keypads:

- Mold Design and Preparation:

– Create and calibrate specialized molds designed for the production of dual-color silicone keypads.

- Initial Silicone Injection:

– Inject silicone into the molds to form the primary layer of the keypad.

- Color Application:

– Apply the first color coating to the silicone base layer and allow it to cure or dry to ensure strong adhesion.

- Second Silicone Injection:

– Apply a secondary layer of silicone in a contrasting color over the cured base layer.

- Final Curing:

– Conduct thorough curing of the dual-color silicone keypad to ensure optimal bonding of layers and enhance durability.

- Quality Control:

– Execute comprehensive quality checks to ensure the keypads meet all design specifications and quality standards.

- Packaging:

– Securely package the finished dual-color silicone keypads for efficient shipment and distribution.

![]()

![]()