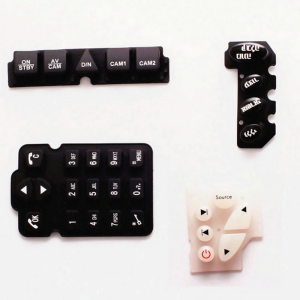

Customized Control Silicone Rubber Keypad For Mechanical Equipment

Control Silicone rubber keypad is made of translucent elastomer silicone material by compression mold tooling,design to provide a tactile interface for controlling various electronic devices and systems.Silicone keypad web thickness and uniformity,key travel,and silicone materials hardness which mainly determine keypad tactile feeling. They are known for their reliability, comfort, and ability to withstand harsh conditions.

Specification

Material: silicone rubber

Color: transparent or any colors

Hardness: shore A 30°~80°

Size: customized size

Tolerance: based on customer’s requirement

Core Technology: laser etching

Molded Way: compression molded

Conductive Way: carbon pills, conductive ink printing, metal domes, metal pills

Surface Protective: PU coating, matte smooth coating, epoxy coating

Performance: aging resistance, cold resistance, heat resistance, chemical stability, waterproof, eco-friendly, durable

Certificate: ISO9001-2015, IATF16949, ROHS

OEM/ODM: available

Samples: free available samples

Packing: PE bag & carton, customized packing

Manufacturing Process

- Material Preparation: High-quality silicone rubber is mixed with additives to achieve the desired properties.

- Molding: The silicone rubber is shaped using compression molding or injection molding techniques to form the keypad.

- Adding Conductive Elements: Conductive carbon pills, ink, or metal domes are integrated to enable electrical conductivity.

- Surface Treatment: Coatings are applied to enhance durability and appearance.

- Customization: Legends and graphics are added using techniques such as laser etching or screen printing.

- Quality Control: Keypads undergo rigorous testing to ensure they meet performance and durability standards.

Why Opt for Our Services

- Guardians of Your Ideas:Your ingenious concepts and designs receive the utmost protection, with our commitment to keeping your

intellectual property secure and confidential.

intellectual property secure and confidential. - In-House Alchemy:Inside our facility, we perform a bit of magic by custom formulating and blending compounds. This wizardry allows us to create solutions that precisely match your unique requirements.

- Design and Engineering Maestros:Our team of design and mold-making experts is your go-to squad for comprehensive OEM/ODM services. They’re the architects and builders turning your visions into reality.

- Manufacturing Versatility:Picture us as a toolkit with various tools. We bring an assortment of manufacturing techniques to the table—be it injection, injection transfer, compression, extrusion, or the enchanting world of silicone liquid capabilities.

- Automated Precision:Our production line isn’t just advanced; it’s like a superhero on autopilot. With automated rubber milling, we ensure not just accuracy but also speedy manufacturing, because we know time is of the essence.

- Quality Safeguarding:Before the production curtain rises, our rubber compounds go through a rigorous exam. We’re the watchmen, making sure that each product meets our high standards for quality.