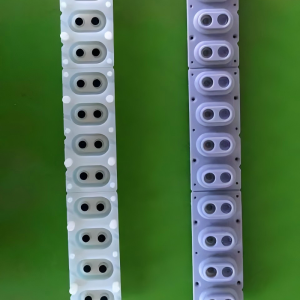

Our rubber machine keys are engineered for use in harsh environments, offering exceptional durability and reliability. Made from high-quality silicone rubber, these keys can be sterilized and washed in water, ensuring easy maintenance and hygiene. The specialized design and production process result in a simple button structure with the use of a high-strength silicone adhesive, eliminating the need for metal fasteners and ensuring stable, long-lasting performance.

These silicone keys offer diverse color options and a unique surface treatment that prevents fading and ensures the key text remains intact over time. The keys provide an exceptional tactile experience with superior toughness and elasticity, resisting external deformation and offering a smooth feel. Non-toxic, tasteless, and safe, they pose no harm to users. The fully sealed design makes them waterproof, dustproof, oil-resistant, fire-retardant, and corrosion-resistant, allowing them to perform reliably in any challenging environment.

Product Specifications:

Place of Origin Xiamen, China

Brand Name OEM

Material Silicone

Shape Custom shape

Color Custom color

Coating PU/Soft matt/Epoxy ect

Secondard processing Soft matt coating,Epoxy coating,PU coating,laser etching,etc.

Additional service metal dome,PCB and flexible FPC/PET assemble

Service OEM Service

Logo:Custom

Certificates:ISO

Advantages of Our Product

– Waterproof and Oil-Resistant: Provides effective protection against moisture and oil, ensuring reliable performance in various environments.

– High-Temperature Resistant: Maintains structural integrity and functionality under elevated temperatures.

– Wear-Resistant: Durable material designed to withstand abrasion and prolonged use.

– Strong Adhesion: Ensures secure attachment and durability across different surfaces and conditions.

The Production Process of Conductive Keypad:

Design: Create a detailed design considering form, key layout, and structure.

Material Preparation: Gather conductive materials like silicone rubber, carbon powder, metals, and backing material.

Conductive Layer Formation: Develop the conductive layer using silicone rubber mixed with carbon powder or metal mesh.

Printing: Use advanced printing methods to apply key patterns and symbols onto the conductive layer accurately.

Assembly: Integrate the conductive layer with the backing material, ensuring precise alignment.

Curing: Subject the keypad to controlled curing to enhance adhesion.