Computer keyboard cover, known as keyboard protector, keyboard skin, keyboard overlay. A computer keyboard cover is typically made of materials like silicone, polyurethane (PU), or thermoplastic polyurethane (TPU). Silicone offers flexibility and durability, providing a soft, protective layer. PU and TPU are more rigid but offer excellent transparency and durability, often used for thin, clear covers. These materials help protect keyboards from dust, spills, and wear. They provide a transparent or opaque layer of protection, making them ideal for maintaining the longevity of your keyboard while keeping it clean and hygienic. Perfect for both home and office use, keyboard covers are available in custom sizes and colors to suit different models and preferences.

Advanced Technology Features:

– Compression Molding Characteristics

– Responsive Silicone Keypad Tactility

– Customizable Shapes and Surface Textures

– Diverse Key Travel and Actuation Forces

– Backlighting Options, Light Pipes, and Clear Windows

– Single-Piece Construction

– Sealing Capabilities with Wrap-Around Designs(protection against dust, liquids, and gases)

– P+R Keypad Technology

– Metal Dome Keypad Integration

Quick Silicone Keyboard Cover Quotation Demands:

Offer 2D/3D design drawings,samples or tell us your basic information

Surface Demands:Legends demands,key & button color demands,spray color coating,key-setting

Protective Coating:PU coating,epoxy coating,matte smooth,plastic & metal keycap(key cover)

Electrically Contact Ways:Black carbon pills,electrically conductive ink printing,metal dome,or only need silicone rubber keycap cover

Contact Resistance:10-250Ohm

Actuation Force:40g-300g

Quantity Demands:FOQ & EAU

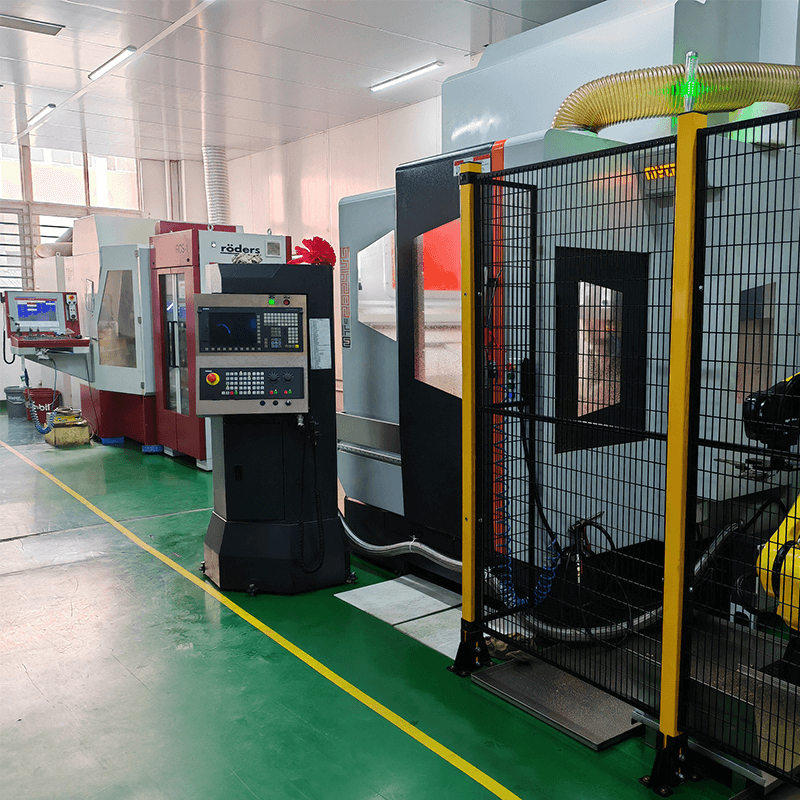

Factory Show

We operate a comprehensive range of plants and equipment to ensure the highest quality production. Our mold-making facilities are equipped with advanced CNC, Mirror EDM, EDM, Slow-speed Wire Cut WC, and other auxiliary equipment.

In addition, our production lines feature 15 sets of rubber compressive machines, and 2 sets of LSR injection machines. To maintain quality standards, we utilize 3D projectors, sealing testers, elasticity measurement tools, durometers, and a qualified QC team.

Furthermore, our mechanical equipment includes an AutoDryer Line, automatic screen printing machines, 3D measuring instruments, automatic high-speed doming machines, die-cutting machines, automatic die-cutting machines, CNC machines, and more.

This combination of professional and automated production lines, advanced mechanical equipment, and rigorous quality control measures ensures that we deliver products of the highest standard.