Silicone conductive metal pill keypad is a type of silicone keypad that incorporates metal pills to meet extremely low contact resistance requirements. These keypads are used in a wide range of applications, including electrical appliances and medical/healthcare devices. The metal pills help support high-performance conductivity, and they are capable of handling voltages up to 24 volts. The metal pill is positioned at the center of the button’s base, and when the key is pressed, it activates the printed circuit board (PCB) underneath. Silicone rubber keypads with metal pills are available in various configurations, depending on factors such as the desired surface legends, color options, functional needs, key cover specifications, and material properties.

Advantages of Our Product

- Durability: Silicone rubber keypads are highly resilient, offering long-lasting performance even in harsh conditions. They withstand repeated use without degradation.

- Flexibility: The material’s inherent flexibility allows for the design of keypads that are comfortable to use and adaptable to various shapes and sizes.

- Temperature Resistance: Silicone rubber maintains its properties across a wide temperature range, from -40°C to 250°C, making it suitable for extreme environments.

- Chemical Resistance: Resistant to oils, solvents, and other chemicals, silicone rubber keypads are ideal for applications in industries where exposure to harsh substances is common.

- Tactile Feedback: Provides excellent tactile feedback with a soft and responsive touch, enhancing user experience and ease of operation.

- Waterproof and Washable: The keypads are inherently waterproof, which makes them easy to clean and ideal for applications requiring frequent sanitation.

![]()

Quickly Quotation Requirements

- Offer 2D,3D design(PDF,CAD,STEP,IGS,slprt.)drawings,or samples

- Include number of legend and silicone colors,of need silicone guide

- With or without carbon pills

- Keypad surface demands:laser etched ,silkscreen,spray coating,uv coating etc

- Quantities to be quoted

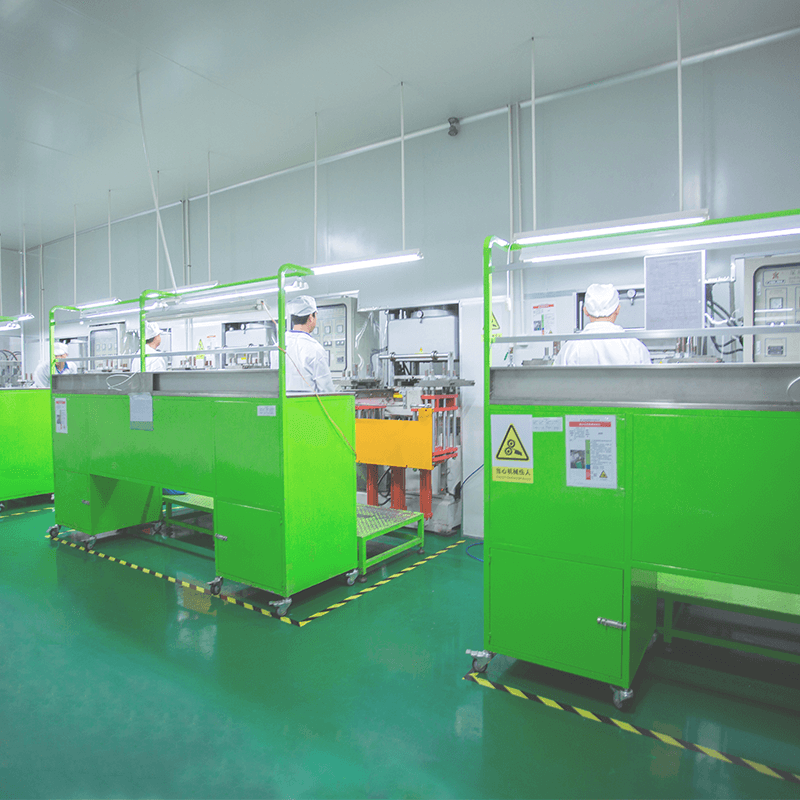

Factory Show

We operate a comprehensive range of plants and equipment to ensure the highest quality production. Our mold-making facilities are equipped with advanced CNC, Mirror EDM, EDM, Slow-speed Wire Cut WC, and other auxiliary equipment.

In addition, our production lines feature 15 sets of rubber compressive machines, and 2 sets of LSR injection machines. To maintain quality standards, we utilize 3D projectors, sealing testers, elasticity measurement tools, durometers, and a qualified QC team.

Furthermore, our mechanical equipment includes an AutoDryer Line, automatic screen printing machines, 3D measuring instruments, automatic high-speed doming machines, die-cutting machines, automatic die-cutting machines, CNC machines, and more.

This combination of professional and automated production lines, advanced mechanical equipment, and rigorous quality control measures ensures that we deliver products of the highest standard.