Surface Treatment for Silicone Keyboard

Overview Backlit keypad, also known as a backlit keyboard, is designed to optimize the characteristics of keypad materials while integrating LED lighting to achieve high-quality backlight effects. Constructed from materials such as silicone rubber, plastic, and metal, it is commonly referred to as a silicone rubber backlit keypad. These keypads leverage the translucent to transparent properties […]

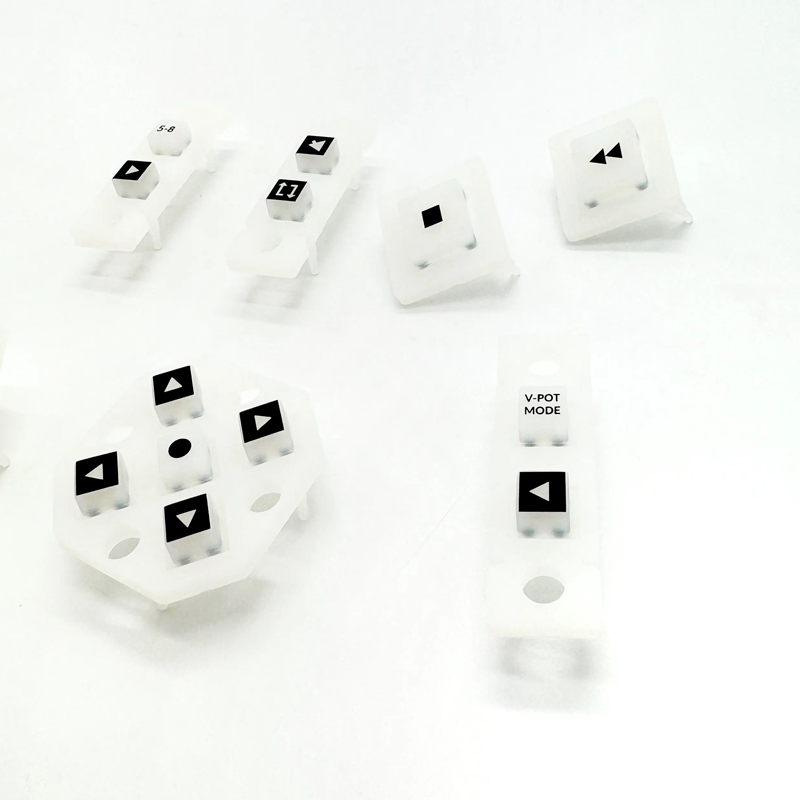

Read MoreOverview: Silicone Compression Molding Silicone Rubber Keypad Buttons with Colorful Treatment are expertly engineered using advanced silicone compression molding technology. Constructed from premium, resilient silicone rubber, these buttons offer superior flexibility, impact resistance, and vibrant, enduring coloration. Ideal for a broad range of applications—from consumer electronics and computer peripherals to industrial control panels—our keypad buttons […]

Read MoreOverview Heat-resistant silicone baking gloves designed for commercial kitchens, bakeries, and food service operations. Provide superior protection against high temperatures, steam, and hot liquids. Non-slip grip ensures safe handling of trays, pots, and baking sheets. Durable, easy to clean, and resistant to stains and odors. Ideal for professional chefs and kitchen staff. Details – Origin:Xiamen, […]

Read MoreOverview The silicone rubber laser keyboard, also known as silicone laser keypad, rubber laser buttons, or silicone laser switches, features a surface coated with vibrant ink using spraying or screen printing techniques. The legends or backgrounds of the keys are created through laser cutting, which allows for LED backlighting. These keyboards are customizable, using translucent […]

Read MoreDescription: As a leading manufacturer and supplier of laser engraved silicone rubber keyboards with backlighting, we meticulously craft each unit using advanced compression molding techniques and premium silicone rubber. This ensures outstanding durability, flexibility, and enhanced tactile feedback. The integrated backlighting feature improves visibility in low-light environments, making it the perfect solution for applications across […]

Read MoreOverview The Elastomer Laser Etching Keypad, also known as a laser-etched keyboard, rubber laser-etched buttons, silicone laser-etched switches, or laser-etched button pads, features a surface coated with vibrant ink through spraying or screen printing. The keypad’s legends or backgrounds are created using laser etching to allow for LED backlighting. These custom elastomer silicone rubber keypads […]

Read MoreOverview Elastomer Plastic rubber laser marking keypad,is also called elastomer rubber laser mark keypad,elastomer silicone laser marking buttons,elastomer rubber laser marking keyboard,elastomer laser marking button pad,whose surface is coated by colorful ink through spraying or screen printing,and keypad’s legends or backgrounds are formed by laser marking for led backlight.elastomer plastic rubber laser marking keypad are […]

Read MoreOverview The Laser Mark Backlight Rubber Silicone Keypad is a customizable input solution made from translucent silicone rubber, designed for applications requiring backlighting. The surface is coated with colorful ink through spraying or screen printing, while the legends or backgrounds are created by laser cutting to allow LED backlight visibility. This innovative design enhances user […]

Read MoreOverview Silicone Button Membrane Keyboards are high-quality keypads made from durable, clear elastomer silicone rubber material. These keypads are typically produced using silicone button compression molding or liquid silicone rubber (LSR) injection molding techniques. Widely used in electronic devices, remote controls, medical equipment, and machinery, they offer excellent tactile feedback, long-lasting performance, and resistance to […]

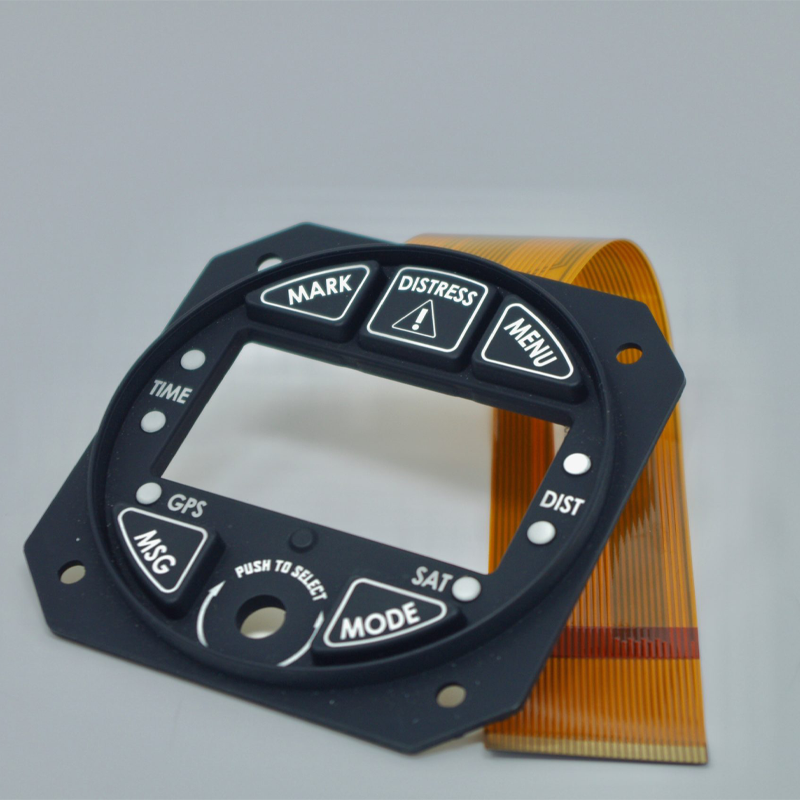

Read MoreOverview The Silicone CAN-bus Keypad is a durable and reliable input device designed for use in heavy machinery and vehicle electronic systems. Featuring a silicone construction, it offers excellent waterproof and wear-resistant properties, ensuring long-lasting performance even in harsh environments. With its compact and sealed design, it is ideal for applications in agriculture, nautical, automotive, […]

Read More