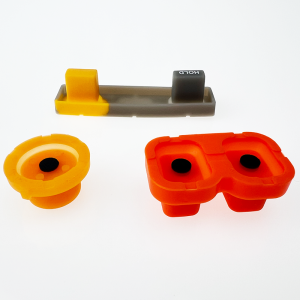

Custom Logo Silicone Keypad Buttons for Enhanced Branding

Overview:

Experience the unparalleled convenience and reliability of our meticulously crafted conductive keypads. Engineered using state-of-the-art silicone compression molding technology, these tactile interfaces ensure optimal electrical conductivity and exceptional durability. They seamlessly integrate into a wide range of electronic devices across various industries, including consumer electronics, automotive, medical devices, industrial controls, and household appliances. Our keypads play a pivotal role in enhancing user interaction, making technology more accessible and user-friendly, thereby significantly impacting everyday life.

Features:

-Color: Customized

-Printing Method: Laser Etching, Digital Printing

-Coating Treatment: PU/Epoxy

-Price Term: FOB, CIF, DDU, DDP

-Shipping Way: By Express/Sea

-Advantage: Durability, Waterproof

-Application: Consumer Electronics, Automotive Interfaces

-Quality: 100% Quality Guarantee

Advantages of Electrically Conductive Ink Printing for Keypads:

Enhanced Conductivity Features

– Versatile Conductive Zones: Achieve design flexibility with various shapes, including irregular or O-ring/rectangular areas for backlighting, catering to diverse design requirements.

– Specialized Solutions: While black carbon pills are standard for most silicone keypads, keypads with irregular conductive zones (e.g., laser-etched or silk-screened silicone rubber) are optimized for superior LED backlighting effects.

Improved Production Efficiency

– Cost Efficiency: Conductive ink printing significantly reduces production costs compared to traditional methods. This technique coats multiple keypad contact zones simultaneously, unlike the manual placement of black carbon pills.

– Automation Advantage: Automated processes streamline production, boosting efficiency and conserving valuable time.

Challenges of Electrically Conductive Ink Printing for Keypads:

Contact Resistance Variance

– Higher Contact Resistance: Electrically conductive ink printing typically shows higher contact resistance (approximately 150-200 OHMs) compared to carbon pill keypads (below 100 OHMs). Achieving precise resistance levels necessitates additional materials and enhanced printing processes.

Durability Concerns

– Ink Wear Over Time: Keypads printed with conductive ink may experience ink wear over prolonged use, affecting durability. Using high-quality ink and ensuring thorough drying during production are crucial to extending the keypad’s lifespan.

![]()

![]()