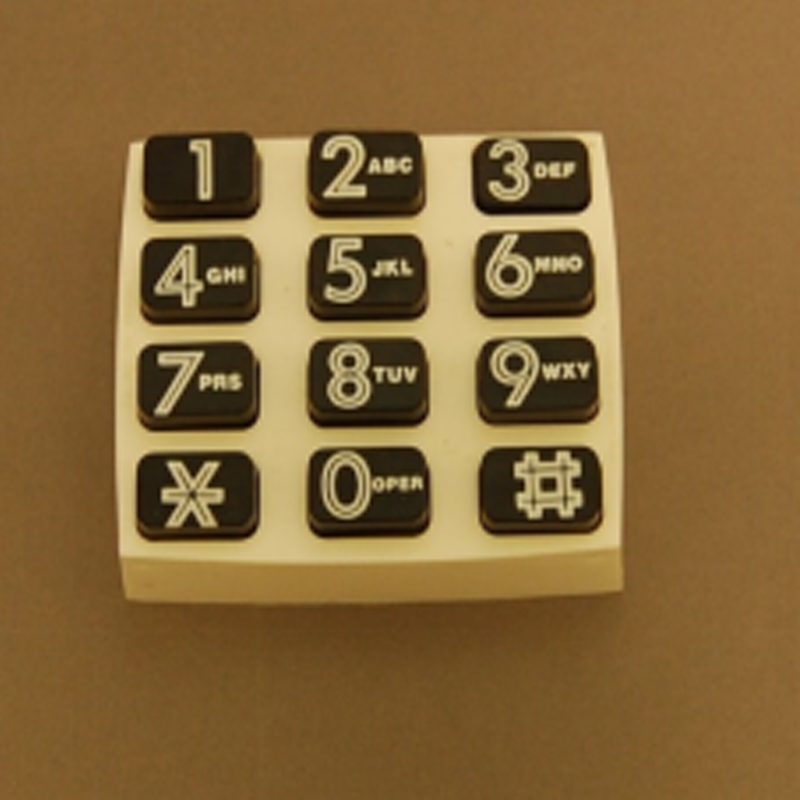

Custom Texture Molding Silicone Rubber Keyboard

Detail:

Textured molds can be used during silicone injection molding to impart specific textures, such as matte finish or stippled patterns, enhancing the tactile feedback of the keys, we can operate them even if we don’t look at the keypad, it also provides a Strong grip, avoid slipping or sliding. Their strengths are obviously used for input and control functions.

Texturing also have a high aesthetic value on the keypad, making it look more appealing and professional. In many industry, such as customer electronics, Medical devices, Industrial equipment etc., require keypads that are aesthetically pleasing and bring a comfortable experience to user.

Different Types of Texture Molding Silicone Keyboard:

- Laser etching

Merit:create intricate designs and patterns; durable

Demerit:expensive; wear off over time

- Molding texturing

Merit:cost-effective; produce consistent textures

Demerit:limited in terms of design; wear off over time

- Spray coating

Merit: cost-effective; a wide range of textures and colors; durable

Demerit:wear off, the coating will crack or peel over time

- Print texturing

Merit: a wide range of textures and colors; durable

Demerit:wear off, the coating will crack or peel over time

Features Include:

| Detection Method | Correlation Type |

| Materials | Silicone Rubber |

| Environmental Friendly | SGS, RoHS |

| Surface Coating | PU Coating, Matte Smooth Coating, Epoxy Coating |

| Place of Origin | Xiamen, China |

| Color | Any color is available (as customer request) |

| Logo | Customized |

| Production Capacity | 50,000 PCS/Week |

| Contact Resistance | 10-200 Ohm |

| Legend | Silk Screen, Laser Etching |

| Conductive Way | Conductive Printing, Carbon Pills, Metal Dome |

| Transport Package | Poly Bag, Carton Boxes |

Why Choose Us?

- Customizeservice

Ability to match Texture Molding board to client branding or application requirements.

- Large-scale factory

Our production lines feature 15 sets of rubber compressive machines, and 2 sets of LSR injection machines.

- high-qualitydocumentation

Our company pass more than ten tests, including ISO 9001:2015 Certification,IATF 16949 Certification, First Article Inspection (FAl),PPAP Report(Production Part Approval Process) etc.

- Meticulous packaging service:

Securely package the keypads to protect against damage during transportation.