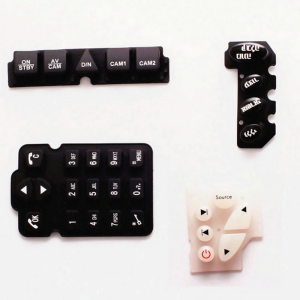

Customized Conductive Rubber Keypad Buttons for High Performance

Experience the superior convenience and dependability of our meticulously engineered conductive silicone keypads. Crafted using precision compression molding techniques, these keypads offer optimal electrical conductivity and outstanding durability, enhancing user interaction. They seamlessly integrate into a diverse array of electronic devices across industries, including consumer electronics, automotive, medical devices, industrial controls, and household appliances. By making technology more accessible and user-friendly, our keypads significantly impact everyday life, ensuring a reliable and tactile interface for various applications.

Characteristics:

– Color: Customized

– Printing Method: Laser Etching, Digital Printing

– Coating Treatment: PU/Epoxy

– Price Term: FOB, CIF, DDU, DDP

– Shipping Method: By Express/Sea

– Advantage: Durability, Waterproof

– Application: Consumer Electronics, Automotive Interfaces

– Quality: 100% Quality Guarantee

– Brand: OEM/ODM

– Surface Treatment: Laser Cutting, PU Coating

The Manufacturing Process of Conductive Keypads:

- Design:Carefully design the conductive keypad, considering form, key layout, and structural integrity.

- Material Preparation:Gather and prepare materials, including conductive elements such as silicone rubber, carbon powder, metals, and the backing substrate.

3.Conductive Layer Creation:Create the conductive layer through methods like blending silicone rubber with carbon powder or incorporating metal mesh.

4.Compression Molding:Utilize compression molding techniques to form the silicone rubber into the desired keypad shape, ensuring uniform thickness and consistency.

5.Printing Process:Use advanced printing techniques to accurately transfer key patterns and symbols onto the conductive layer.

6.Assembly:Seamlessly integrate the printed conductive layer with the backing material, ensuring precise alignment of keys.

7.Curing:Place the assembled conductive keypad in a controlled curing environment to ensure strong adhesion and durability.

8.Quality Control:Conduct thorough testing for sensitivity, electrical conductivity, and visual aesthetics to meet high-quality standards.

9.Packaging:Carefully package the quality-tested conductive keypads to protect against contaminants and damage.

This comprehensive process ensures that our conductive keypads are reliable, durable, and meet the highest industry standards.

Why Choose Us:

– Curing Presses: Operate 24/7 to ensure efficient production and timely delivery of bulk purchases.

– Fast Delivery: Quick turnaround times to meet your deadlines.

– CNC Technology: Advanced CNC machines for precision and quality.

– Quick Customization: Free proofing services for rapid customization to meet your special requirements.

– Extensive Mold Availability: Access to 5000 sets of molds at no cost. For non-standard sizes, we offer one-time mold opening with lifetime use.

– Large Inventory: 2000 square meters of spot stock available, adhering to American and European standards, including winning bids.

– No Minimum Order Quantity (MOQ): Flexible production with no minimum order requirements.

– Immediate Shipping: As soon as your goods are ready, we will deliver them for you