Factory Prices for Premium Conductive Carbon Pills

Overview:

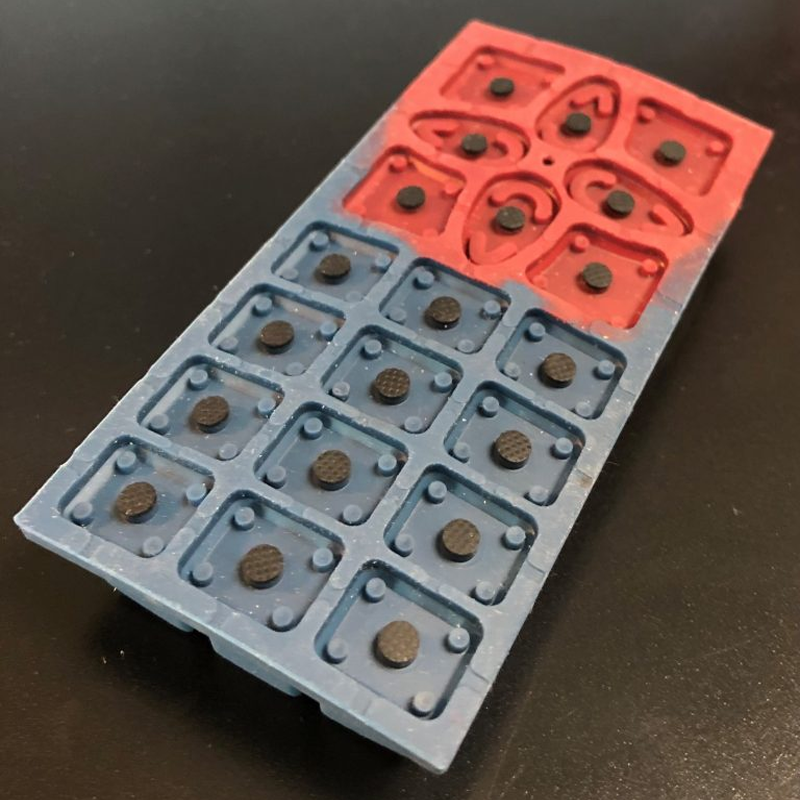

Conductive carbon pills, also known as carbon beads, are small particles made from conductive carbon material. These pills are typically produced through compression molding, a process that ensures uniformity and optimal electrical properties.Commonly found in electronic connectors, conductive carbon pills exhibit exceptional conductivity, guaranteeing reliable electrical connections. They are widely utilized across electronics, communication technology, and medical devices, enhancing the stability of device connections.The effective conductivity of these carbon pills significantly improves the performance and reliability of electronic products, impacting various aspects of our daily lives that are closely linked with technology.

Characteristics:

| Feature | Details |

| Dimension and Size | Customized |

| Color | Customized |

| Sample | Available |

| Material | Carbon Particles, Carbon Fibers |

| Lead Time | 15-25 Days |

| Advantage | Excellent Conductivity |

| Delivery Term | Sea/Express/Train |

| Application | Electronic Connectors |

Production Process:

- Raw Material Selection: Careful selection of conductive carbon materials, including particles, fibers, and black carbon.

- Mixing and Pulp Formation: Blending the selected carbon materials with a binder to create a moldable pulp.

- Molding: Injecting the mixture into molds to achieve the desired pill shapes.

- Sintering or Curing: Subjecting the formed pills to controlled temperature treatments to ensure stability and conductivity.

- Surface Treatment: Optionally applying protective coatings or enhancements to improve properties.

- Quality Inspection: Conducting rigorous testing to ensure compliance with specified standards.

- Packaging: Packaging qualified pills for shipment or integration into end products.

Fast Quote Requirements:

- Quantity:Please specify the required quantity.

- Specifications:Provide detailed information regarding size, conductivity, and temperature resistance.

- Customization Needs:Outline any specific customization requirements.

- Delivery Location:Indicate the delivery destination.

- Delivery Time Constraints:Mention any deadlines or time constraints for delivery.

- Additional Requests:Include any special requests or considerations.

Factory Overview:

We operate a comprehensive range of plants and equipment to guarantee the highest quality in our production processes. Our mold-making facilities are equipped with advanced technologies, including CNC machining, Mirror EDM, EDM, Slow-speed Wire Cut (WC), and various auxiliary equipment.

Our production lines feature 15 rubber compression machines and 2 liquid silicone rubber (LSR) injection machines. To uphold our quality standards, we employ 3D projectors, sealing testers, elasticity measurement tools, durometers, and a skilled quality control (QC) team.

Additionally, our mechanical equipment includes an Auto Dryer Line, automatic screen printing machines, 3D measuring instruments, high-speed automatic doming machines, and both manual and automatic die-cutting machines, as well as CNC machines.

This integration of professional and automated production lines, along with advanced mechanical equipment and stringent quality control measures, ensures that we consistently deliver products of the highest standard.

![]()

![]()