Silicone elastomer 4×4 button keypad is a flexible and durable input device featuring a 4×4 matrix layout, commonly used in electronics like remote controls, security systems, and industrial equipment. Made from high-quality silicone elastomer, it provides excellent tactile feedback, water resistance, and long-lasting performance. Its customizable design allows for printed symbols, backlighting, and various key shapes, making it ideal for both consumer and industrial applications requiring reliable and responsive keypad interfaces.

Details

– Origin:Xiamen, China![]()

-Brand:OEM

– Keypad Material:Silicone

– Key Features:Durability, Chemical Resistance, Weather Resistance, Temperature Tolerance

– Applications:Home Appliances, Industrial Equipment

– Custom Orders:Accepted

– Color Options:Multicolor Printing

– Materials:Silicone, PVC, PET, PC, Metal, Adhesive-Backed Materials

– Environmental Considerations:Eco-friendly inks and materials

– Size:Customizable

– Logo:Custom Branding Available

– Accepted Artwork Formats:AI, PDF, CDR

One-Stop Service for Silicone Rubber Keypads

- Design Consultation: Expert guidance on design optimization and manufacturability to meet your specific requirements.

- Prototyping: Creation of functional prototypes to validate design and performance before mass production.

- Custom Molding: Precision silicone compression molding to produce high-quality, durable keypads with custom shapes, sizes, and colors.

- Printing and Finishing: Advanced techniques including silk screen printing, laser etching, and surface coatings for clear legends and enhanced durability.

- Quality Control: Rigorous inspection processes to ensure product consistency, performance, and compliance with industry standards.

- Assembly and Packaging: Comprehensive assembly services and custom packaging solutions to streamline logistics and reduce overhead costs.

- After-Sales Support: Ongoing support and service to address any issues and ensure continued satisfaction with your silicone rubber keypads.

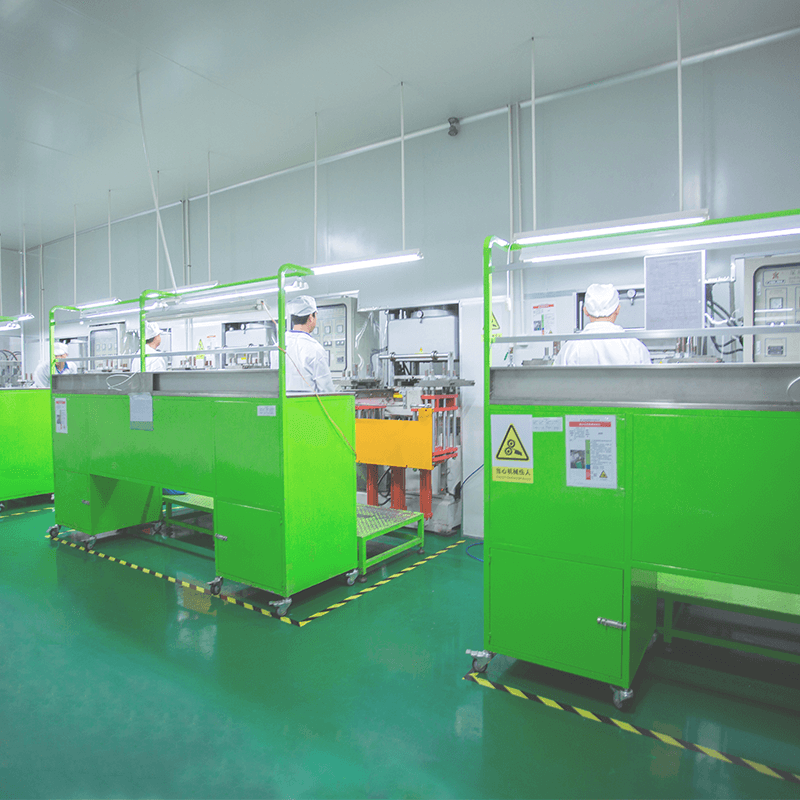

Factory Show

We operate a comprehensive range of plants and equipment to ensure the highest quality production. Our mold-making facilities are equipped with advanced CNC, Mirror EDM, EDM, Slow-speed Wire Cut WC, and other auxiliary equipment.

In addition, our production lines feature 15 sets of rubber compressive machines, and 2 sets of LSR injection machines. To maintain quality standards, we utilize 3D projectors, sealing testers, elasticity measurement tools, durometers, and a qualified QC team.

Furthermore, our mechanical equipment includes an AutoDryer Line, automatic screen printing machines, 3D measuring instruments, automatic high-speed doming machines, die-cutting machines, automatic die-cutting machines, CNC machines, and more.

This combination of professional and automated production lines, advanced mechanical equipment, and rigorous quality control measures ensures that we deliver products of the highest standard.